Project no.1

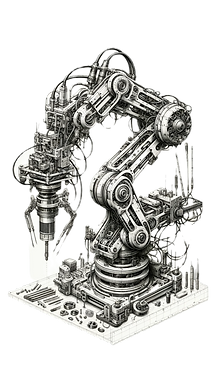

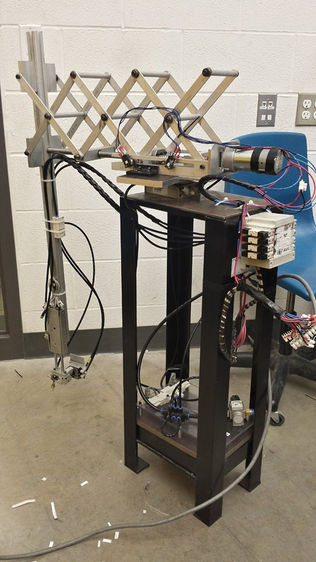

Robotic Arm

Project Role:

-

Project Manager: Pneumatic System & Electrical Circuit Wiring

-

Primary Responsibilities: Led the design of the pneumatic system and managed the hardwiring of electrical components for the Robotic Arm project.

Project Summary:

The Robotic Arm project involved developing a crane-like structure with truss linkages, designed for precise alpha-numeric tile manipulation. The arm was engineered to rotate 180 degrees and move horizontally at speeds up to 25 inches per minute using a motorized ball screw system. Additionally, a vertical Z-Axis with a pneumatic cylinder and vacuum gripper was incorporated, enabling the arm to pick up tiles from varying heights and accurately place them onto a turntable without toppling.

Control & Functionality:

The Robotic Arm is operated via a user-friendly control box equipped with pushbuttons, switches, and knobs. This control box is connected to the arm through a cable, allowing the operator to control the extension and retraction of the arm using a momentary-momentary switch. The movement speed is regulated by a motor controller, and the total travel distance is monitored by limit switches with LED indicators, ensuring precise operation. The system supports both Manual and Auto modes, providing flexibility in operation.

Outcome:

Successfully delivered a functional Robotic Arm capable of precise manipulation, showcasing expertise in both pneumatic and electrical systems. The project emphasized hands-on experience in system integration and control systems, critical for complex automated machinery.